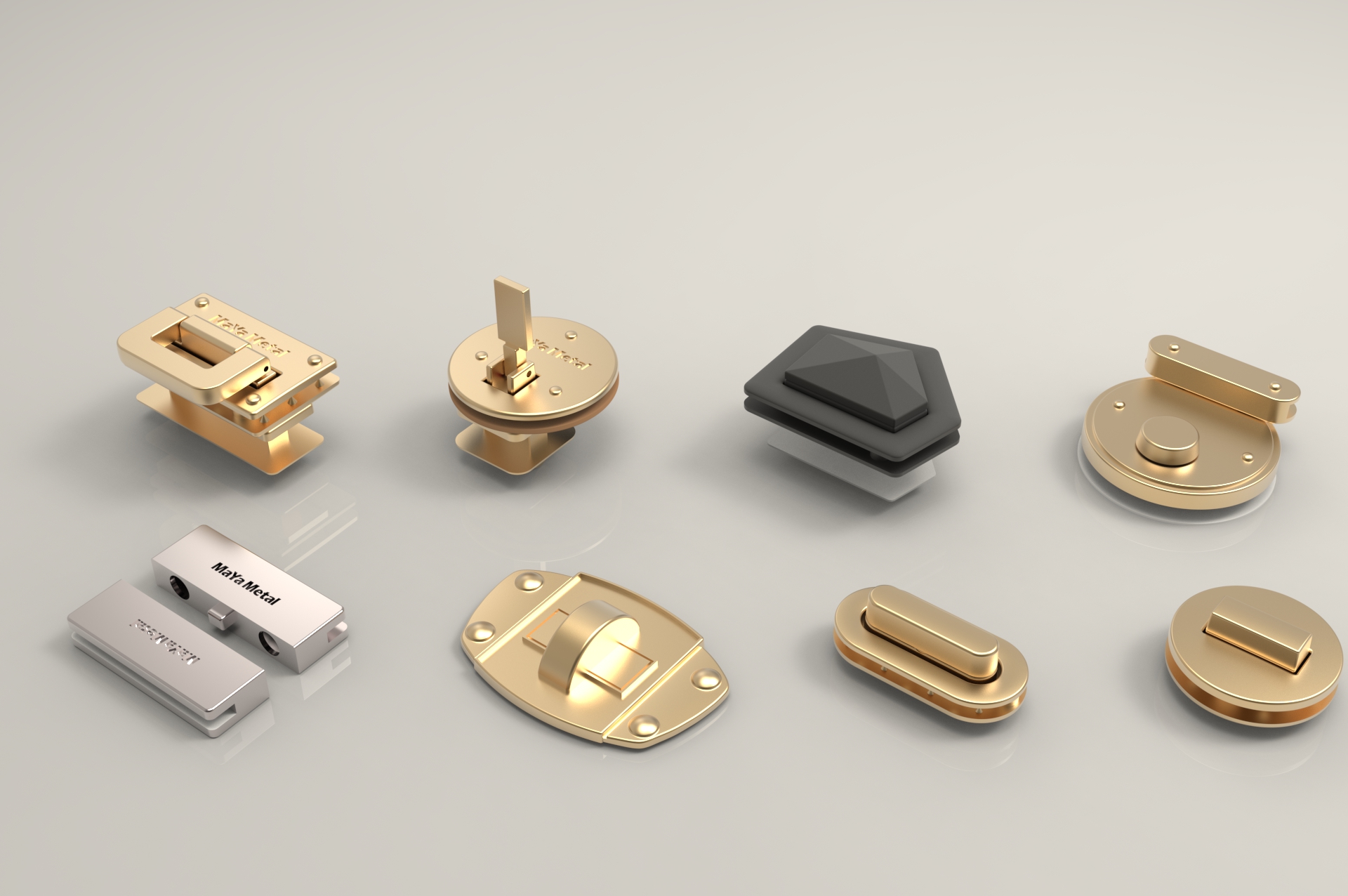

No.1 Custom Stainless Steel & Brass Bag Hardware Manufacturer

Custom high-quality bag hardware and trunk hardware

Over 17 years of factory experience

Get an instant online quote in minutes

Samples ready in as fast as 7 days, Orders delivered in 15 days.

Our Services

Technology Consulting

Our engineers will evaluate the feasibility of the plan and give professional advice based on the idea or design provided by the customer.

Products Design

MaYa Metal offers design support services to customers who need help designing their bag hardware components or developing customized solutions.

3D Printing

MaYa Metal’s 3D printing services are valuable for bag makers and designers who need to develop high-quality and functional hardware components for their products.

Prototype Quick Making

Product Customization

MaYa Metal’s in-stock and bulk hardware options are made from high-quality materials such as zinc alloy, brass, and stainless steel, with competitive pricing and a 1pcs MOQ.

Sourcing Services

We are located in Dongguan, the world’s manufacturing hub, where we can meet almost all your product needs. If you don’t want to spend your precious time, our procurement team will be happy to assist you with all your requirements.

Why choose us

Great Communication

Our professional team offers quick responses and patient service, saving you valuable time.

Shorter Lead Time

Our advanced processing flow and impeccable production management ensure on-time delivery and superior quality.

High Quality

With strict quality control and a thorough inspection process, we guarantee the highest quality of our products.

Reasonable Price

Our sophisticated technology and high-precision production equipment ensure stable, durable, and competitively priced products.

Flexible MOQ

We are committed to supporting your start-up brand and growing together with you. Our small MOQs reduce customer risk, allowing you to try new products at a lower cost.

Perfect after-sales service

At MaYa Metal, we are committed to solving any problems you encounter, anytime and anywhere.

How to work with Maya metal

1. Quote and Payment

2. Products design

3. 3D plastic mold making

4.Prototype making

5. Bulk production

6. Packing and shipping

Accuracy in Each Piece: Welcome to Maya Metal Craft Factory

Maya Metal prides itself on being a reliable metal craft factory that produces high-quality, bespoke components for the fashion and leather goods industries. With hands-on expertise over the years, precision engineering, and devotion to craftsmanship, we have become a prominent bag hardware manufacturer for brands that look for durability as well as design.

Personalized Bag Hardware Made to Last

Your design is worth more than generic hardware. That’s why we provide fully customized solutions for bespoke bag hardware so brands can craft items that not only work but also add to the overall look of their product. From imprinted logo plates and handles to zippers, locks, clasps, studs, and ornaments—we do it, and we do it to perfection.

Whether minimalist chic or show-stopping detail, our team requires every part to be engineered with precision and consistency.

The primary manufacturing processes for bag hardware accessories are: zinc alloy die casting, Stainless Steel Metal Injection Molding, brass or stainless steel forging, precision CNC turning, and precision CNC engraving/milling.

The key manufacturing processes for bag hardware manufacturer accessories involve several advanced technologies:

Zinc Alloy Die Casting – Pressure casting of molten zinc alloy is done in molds to quickly create intricate structural shapes in mass production of clasps and ornamentation.

Stainless Steel Metal Injection Molding – Compacting metal powder to shape and then sintering at defined temperatures, producing high-density, corrosion-resistant precision parts such as lock cores and rivets.

Brass/Stainless Steel Forging – Hammer impact shaping to plastically deform metal blanks, adding material density and mechanical toughness, generally used in load-carrying components such as D-rings.

Precision CNC Turning – Program-controlled cutting tools process rotational components like shafts and threaded components efficiently.

Accuracy CNC Engraving/Milling – Multi-axis CNC machines carry out micron-grade 3D surface cutting for artistic elements like brand logos and textures.

Synergistic application of these processes guarantees hardware accessories to be industry high-end compliant in quality, durability, and aesthetic value.

Fine Detail Lost-Wax Casting Experts

With our own in-house lost-wax casting factory, we produce highly detailed, resilient metal parts with utmost precision. Ideal for sophisticated shapes and finely detailed textures—excellent for brands wanting to stand out on custom bag hardware with distinctive patterns or signature details.

By blending the old methods with new technology, we provide consistent performance at scale without compromising the artwork’s quality in each piece.

Durable Premium Stainless Steel Bag Hardware

For the brands that favor strength and long-term longevity, we have a specialized line of stainless steel bag hardware. This one is best suited for functional items like strap buckles, rings, and D-loops, particularly for bags that will see heavy wear or outdoor use.

Why Maya Metal?

- Completely customized solutions for multiple designs

- Castings and finishing in-house under rigid quality control

- Rapid prototyping and sample creation

- Environmentally friendly production with minimized waste processes

- Partnered with international designers, brands, and manufacturers

Begin Your Project With Us

Whether you are designing your next bestseller handbag or a custom leather line, Maya Metal is here to deliver the touch that makes your product stand out. Being your single-source metal craft factory, we don’t only produce hardware—we assist in turning your innovative imagination into reality, piece by piece.

Let’s create something exquisite together.

Get in touch with us today and talk about your custom bag hardware requirements.

FAQs

Can I order small or bulk quantities from Maya Metal’s metal craft factory?

Yes, our metal craft factory also provides support to small custom orders as well as high-volume, high-level orders. Being a small design studio brand does not make a difference to us; we can accommodate orders in bulk or in small quantities, so you do not have to compromise when it comes to quality or craftsmanship.

Can Maya Metal create custom bag hardware?

Absolutely. We specialise in custom bag hardware that fits your brand’s design and functionality. Whether it be in logos, special finishes, and shapes, we are able to take whatever ideas you may have and bring them to the best of our ability with precision and detail, no matter how complicated your concept may be.

What is a lost-wax casting factory, and does Maya Metal offer this?

A lost-wax casting factory is a high-precision process of making detailed and high-quality metal parts. Yes, Maya Metal does all of its own lost-wax casting to create complex hardware with a clean line and fine texture, perfect at the highest levels of quality or in function-specific bag designs.

Is Maya Metal a reliable bag hardware manufacturer?

Yes, we produce stainless steel bag hardware, which is durable. Our stainless steel parts are corrosion-free and suitable for straps, buckles, and high-use. It is great for the luxury bags as well as outdoor looks, made to withstand rougher use.